Chapter Four: Where to Start—Your Suppliers

“Waste is worse than loss. The time is coming when every person who lays claim to ability will keep the question of waste before him constantly. The scope of thrift is limitless.”

~Thomas A. Edison

One manufacturing business I consulted for had developed a great relationship with their supply base. Things were going along well, but a top supplier was delivering a product which continually had problems—counts, quality issues, and such—although they were competitive in price to other suppliers, they weren’t so competitive that it was worth dealing with constant issues.

As a first step I had a meeting with the supplier, and laid out clear expectations to make sure they understood they were being measured, and how they were being measured. Suppliers need not agree with the measurement, they just need to know that it’s in place, and that it will affect future purchasing decisions. After a couple months of good data/metrics exchange where everyone seemed to be on the same page, their metrics were not improving (delivery and quality).

Based on little or no improvement, I asked for a corrective action, and information about how they would meet our expectations. Adding inventory was their answer. After conversations with the supplier, we agreed adding inventory only hid problems and we would instead conduct a VMS session to see if we could identify internal issues holding them back.

This is a great step for any supply chain manager. It provides incredible visibility for future negotiations as you learn areas of waste to focus on for price reductions. I met with their team and conducted a value stream mapping session. During the process, I quickly identified a few problems, and came up with suggestions on how they could meet our targets. These included:

- Large batching of parts prevented items from getting through quickly and took a considerable amount of time to clear the quality inspection stage.

- Single point scheduling. There was little to no flow within the shop. A person was responsible for moving jobs along instead of letting the work naturally flow.

Changing these two items dramatically changed delivery metrics—moving them from the worst performer to the top 10 within a few months.

Developing a Long-Term Philosophy of Waste Reduction

You first attack the low-hanging fruit of waste through what’s often referred to as a “Kaizen blitz” in manufacturing, or a “process blitz” for upstream processes. The idea is to have a short-term, intensive effort to target big opportunities for quick improvement and immediately implement solutions. This kind of quick-hit, blitz-type effort early in your lean implementation, can be a great way to gain early wins and to bring about focused thinking on ways in which lean principles apply to your firm’s environment.

At the end of the day though, you have to think long-term, and develop a philosophy that will work for your business.

Paradigm Shift

You learn this certain way to see. You get to know waste—where it is—why it is; off the top of your head when you’ve been around it often enough. Once you know what to look for, waste leaps out. If you walk into a restaurant, you can see how processes flow (or don’t) and you can see this at the airport too. Airports are great examples of an inefficient supply chain where you hurry up and wait all the time. Hurry up and wait happens a lot with business too.

Once you really get into lean practices, you just kind of live and learn lean, and get into these patterns of observation. You learn to see. It takes time to do that but after a while it can become second nature. For management. For employees. You want all the employees to get into this lean view and to change how they see the workplace. The paradigm shifts—that’s what you want. You want them to see and discover the waste themselves. Without you asking.

Some industries have really taken to lean. Hospitals have changed their whole philosophy. You’re seeing a change in most western countries. Previously you’d just sign in and wait. Today most hospitals have systems where they walk you through different avenues. If you’ve got flu you go this path, and if you have a broken arm, you go another path. They’re really attempting to minimize all the unnecessary steps. Their paradigm and philosophy has shifted.

Eliminate Waste in the Supply Chain and Leave Only Value

A supply chain can be an ad-hoc and unwieldy creation. The more steps along the path, the more waste creeps in. This applies if it’s a production process for a physical product, an information flow system, an application process—anything that is delivered to an end customer. Taiichi Ohno, of Toyota Production System, came up with the seven manufacturing wastes: Overproduction, Inventory, Over-processing, Correction, Waiting, Conveyance, and Motion. Some typical examples of waste are:

- Lead time—excessive waiting times. Think about all the waste that exists because you are waiting for material, people, customer orders upstream processes—all the things needed before you can perform your work.

- System complexity—extra, unnecessary, steps and complex, confusing processes.

- Transport—unnecessary movement of product. This includes underutilized equipment, inter-plant shuttles, and other transportation wastes.

- Space—holding places for unnecessary inventory such as warehousing costs.

- Inventory—inactive raw, work-in-process, or finished goods. You’ll find this is caused by overproduction, forecasting errors, long lead time, and batching.

- Human effort—this is activity that does not add value, and is often due to an inability to engage team members, and failing to work together collaboratively.

- Packaging—containers that transport air or allow damage

Value Stream Mapping

Value stream mapping is a fantastic visual and communications tool to get everyone on the same page. When you create, and use value stream mapping you are really making sure that everyone understands the process involved in either physically making a product, or delivering a service. It helps makes the intangible easier to follow and identifies how long things take and how many people take to make it. It’s really a way to ensure that everybody agrees this is the process, and then to point out opportunities.

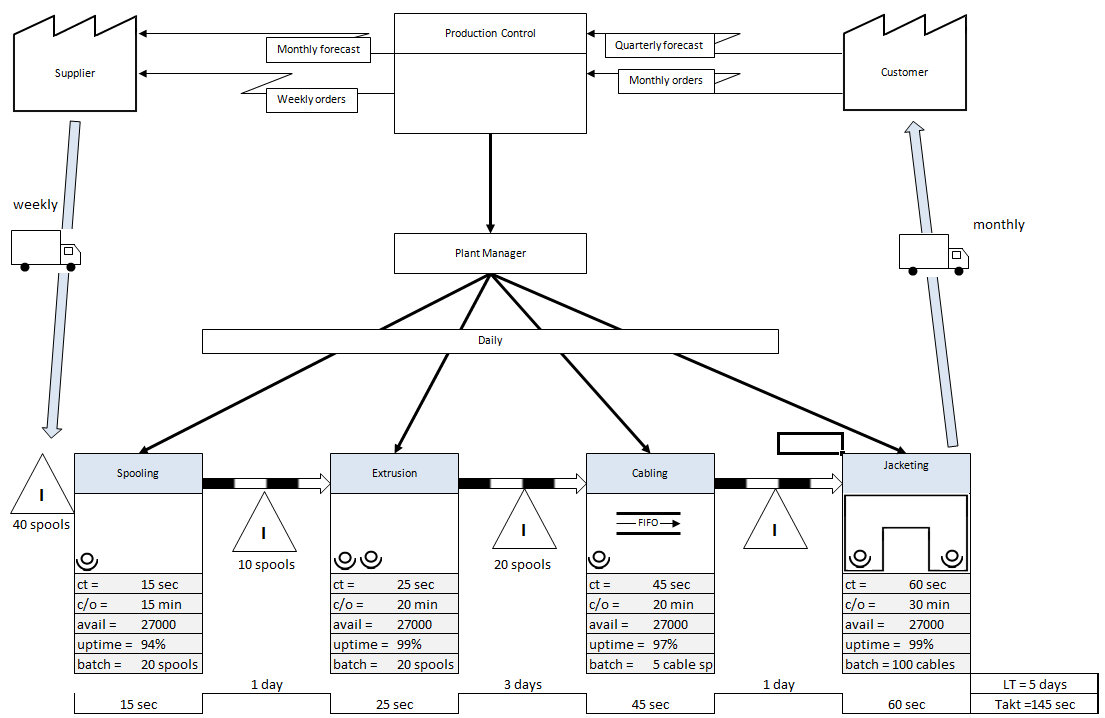

FIGURE 4.1

Value Stream Mapping

Even if I’m physically not making one I have this value stream map in my head of what things looks like today, and the future state of what it will looks like when we are done. To me you put those next to each other and this lets people know that there is a vision.

It involves learning too; when I’m making them I’m not just sitting at a desk making a pretty document—it’s an engaged process, and commonly you’ll have multiple people working on a VSM. It’s important to be physically going and seeing things, observing the current process that you’re trying to describe.

Developing a Current State Map

I recall working on a return process. Customers would return products, and the return would go into a black hole. It would go into a return area, and staff would either have it repaired or replaced… in time. You could buy a new product in less than a week, but to get a product replaced or repaired, the company might take anywhere from 6 to 8 weeks and sometimes even longer depending on what exactly the product was.

Sometimes Joe would take care of this and sometimes Bob would take care of something else. They thought it was hard to get components. Essentially, there wasn’t a defined process. There really were no standards in place and this ultimately led to customer dissatisfaction. When a customer returns something, they want to know the status, to basically know where this is at.

This also didn’t help product improvement., because there was no root cause analysis and no understanding of what went wrong; so you could never use the valuable data you get from returns, to fix design faults on future models or future designs. Walking through a current state map, I could see there was just a ton of stopping and waiting in there and a lot of handling too; from customer service, to receiving, to the repair guys, all the way through; and then getting it back to the customer.

I identified the most common process that occurred, what happened with 60% – 80% of the returns, and then said, “What if we implemented a checkpoint system in there, and ultimately make things visible too.” When a part came in or was returned, it was put on a schedule board, which showed where it was at. Has Bob looked at that? Well check the board and you’ll soon see. I implemented a report system which detailed what exactly was defective, and if it needs the expertise of the engineering team, or this was a defective component, or whatever the situation was. There was kind of multiple path philosophy there, depending on the skill-level of the repair guy or technician—so you could quickly see where it needed to go. Everything was visible through the whole process until ultimate hand—off back to the customer.

At the end, I got the entire returns/repair process down to 3 to 4 weeks, just by creating visibility and accountability. There were no huge changes in the way the company did things or in the actual repairs. Just in the documentation in this whole process; so, that’s where you start. Current state map is a value stream map of the current state, basically; so if I walk on your production floor or into your office that’s the process I should see going on.

Talk to Suppliers

The number one lesson I want businesses to take away from this book is that at some point you will need to talk to your supplier base. Meet your supply base. You can’t get to everyone, but focus on the top 10 or largest spend which should ultimately drive the largest impact. Flow, in the lean supply chain begins with supplier engagement. Visibility and data sharing are key components. Supplying metrics such as customer usage is critical. This sets the supply chain pace. To develop lean suppliers, organizations should include suppliers in their value stream. They should encourage suppliers to make the lean transformation and involve them in lean activities. This will help fix problems and share savings.

Sit face to face with your suppliers and build a relationship. Ideally, you should be learning about their process. Don’t focus on current state too much, but you want to gauge the level of their engagement, their willingness to work with you, and desire to grow. Find out what they want. Is it sales, profitability, or better forecasting? Don’t worry about what you need initially. Laying out clear expectations are critical. Make sure each supplier knows what is expected of them and by when.

When you’re working to create your Sales, Inventory, Operations and Production Plan (SIOP) invite your top 10 suppliers and customers to the monthly (or otherwise) SIOP meeting. Work in collaboration with them to reduce lead times and brainstorm ideas for how you can create a lean supply chain. When all participants of the lean supply chain can see if they are operating in cooperation with others, you can more easily identify problems, determine root causes, and develop solutions to solve problems. Value Stream Mapping (VSM) helps break down processes and gives you the ability to rebuild your workflow more effectively. PDCA is another useful tool: Plan, Do, Check and Act. All members of the supply chain should use such tools in the pursuit of increased value to the customer.

Virtually every conversation with suppliers should emphasis a lead time reduction. Quick turnaround allows the supply chain to be much more responsive and flexible. The shorter the lead time the less variation in demand is also likely.